🔋'Aldi-Brand' Batteries

Sodium-ion batteries replacing lithium-ion this year? The cheap alternative is nearing energy densities of some lithium-ion cells.

Press the heart button on this article, yes you! I would greatly appreciate it :)

While I resist the urge to make a salt pun in the title, the world eagerly theorizes who will de-throne Li-ion batteries as the king in the energy storage/electric vehicle sphere with names like solid-state, lithium/silicon anodes, lithium-air, lithium-sulfur, or even hydrogen fuel-cell chief among them. Instead of charging forward, could the real answer be something steadily lagging behind?

This of course is the sodium-ion battery (SIB), which you will have to dig back to June 15, 2022 just to find the last mention of SIBs in this newsletter. That piece, Why So Salty, I discuss the pros and cons of SIBs and why given higher lithium prices and the “bull case for batteries” would shift more attention to SIBs in the future.

Not a year later and it is safe to say with some new developments and the lithium price freaking out everyone from Elon Musk to the Chilean government, sodium has some renewed interest. Take google trends for both Li-and Na-ion for example. While interest for Li-ion is generally higher (to be expected), Na-ion has made a surge in 2022. Partly from rising lithium prices and partly for reasons I discuss below.

If you didn’t read my first article on SIBs, it is important to understand the nuance of the technology so we can get a realistic sense of its future prospects. Overall the way the SIB works is identical to the LIB albeit less energy dense generally, meaning there is less energy stored for the same mass or volume (gravimetric and/or volumetric energy density). The sodium analogues on cathode side are less stable due to the larger sodium ion, leaving materials like Prussian White (see TECHtricity for more) as a top choice. Similarly, graphite which is the popular anode for lithium-ion is not stable with sodium, leaving a similar carbon containing material called hard-carbon as the top choice. Overall this less mature and studied area leaves some optimization to be had in the cyclability and manufacturability of these materials as well. For automakers, fitting more batteries into a vehicle without compromising the vehicles range given volume and weight limits could spell a serious challenge as well. The main benefit is cost with sodium multiple orders of magnitude more abundant and more evenly distributed in earth’s crust than lithium. There are further potential cost savings in the electrolyte as well as increased thermal stability/performance benefits.

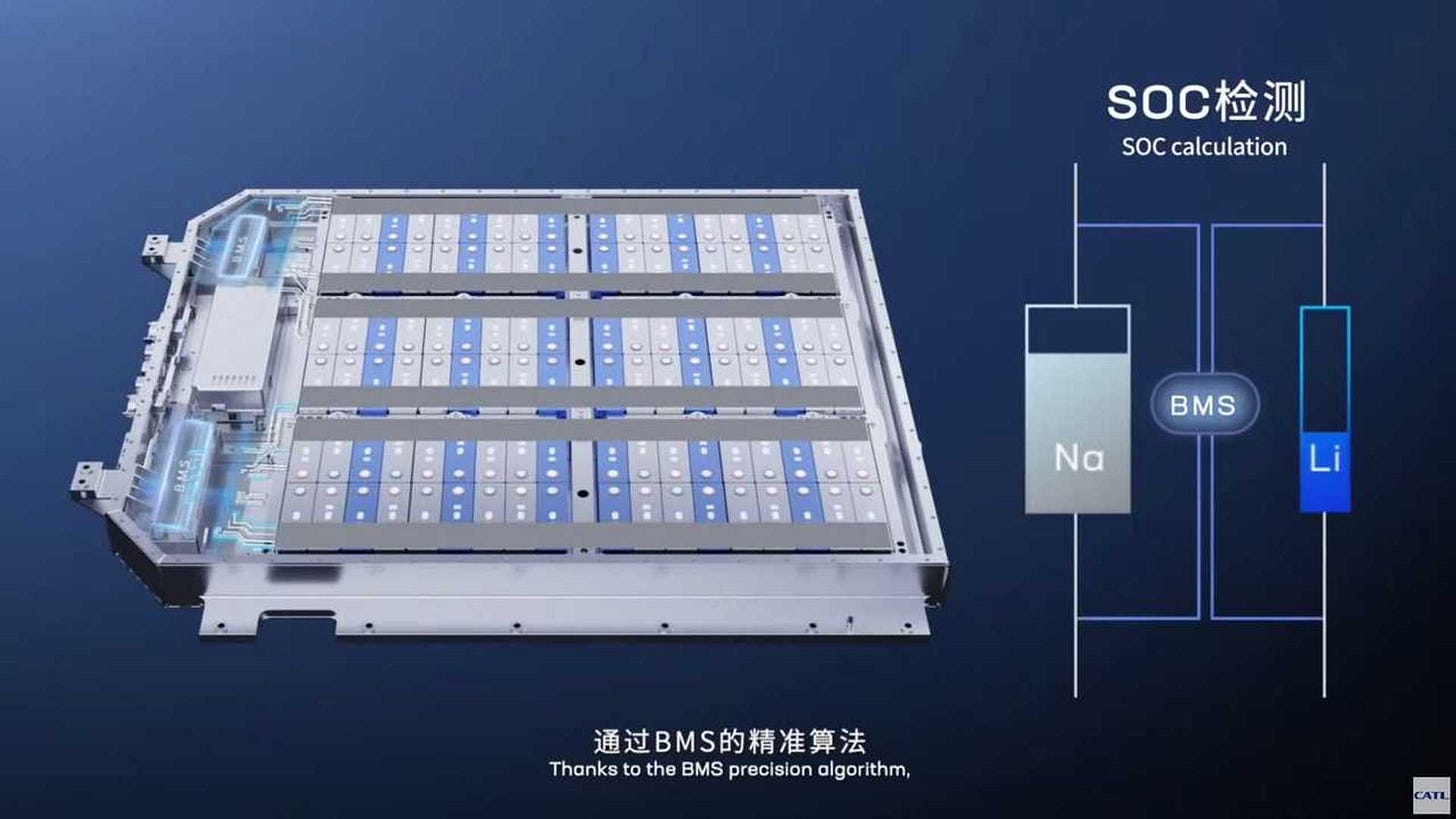

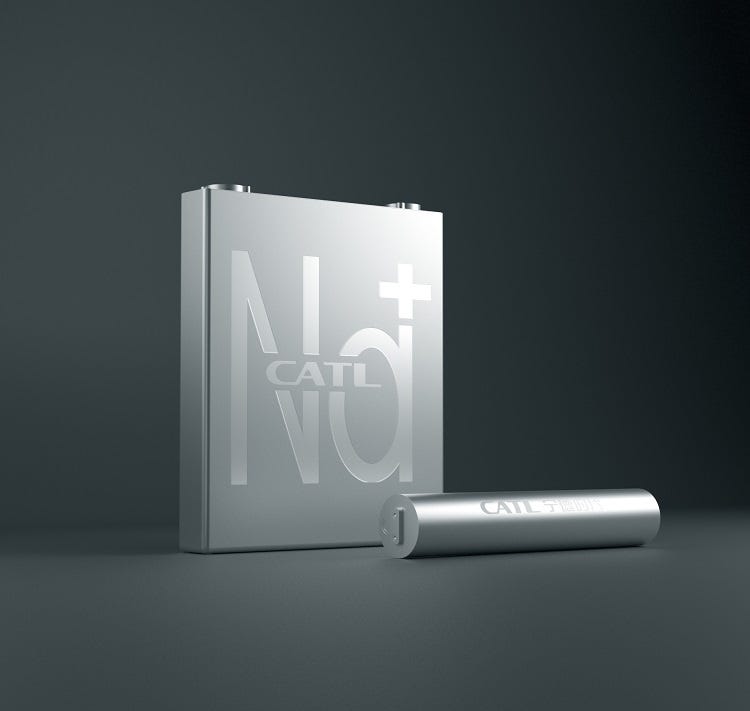

Last month, CATL were rumored to supply Chery and BYD SIBs as early as this year with sodium-ion batteries with energy densities nearing that of LFP1. There is not much info other than an official tweet and knowledge that CATL has been hard at work preparing production of their SIBs since 2021. However, this is only a hybrid Na/Li-ion approach2, likely to achieve energy densities suitable for a car.

BYD is an emerging EV company mainly serving China, but increasing there sales abroad to places like India, Brazil, Spain, and the UK for example. They also manufacture some of their own batteries with plans to increase, but they also have agreements with CATL for batteries like I mentioned. The company also has strategic partnerships with the likes of Toyota, Tesla and Nvidia and has some work in electronics as well. Chery on the other hand appears to be just an auto manufacturer with in house research, but sources their batteries elsewhere including CATL. It is another mostly Chinese automaker with some exposure overseas. Neither company sells in the US.

Will sodium-ion actually be in cars soon? Perhaps in China this year or next. This makes sense as many vehicles are on the smaller side which may be able to justify the less energy density and the manufacturing base is closer. Okay, but will they actually be in US cars soon? In short, probably not, at least a few years away. First, the US consumer is really picky about range and performance which does not help the case for sodium in the US. CATL has deals with a few US automakers, but none with SIB announcements. It is likely that Tesla could be the first adopter with good relationships with CATL and BYD and Musk who is positive towards SIBs, but this could just be in overseas models. Further, Natron, the largest SIB company in the US is only set up to start manufacturing sometime this year, so it may be some time before we see stateside adoption since automakers are keen to take advantage of inflation reduction act credits.

With lithium prices coming down in 2023, there may be some relief and less pressure to develop a different technology. However, if lithium remains in a structural supply/demand imbalance, expect Na-ion to re-capture the interest due to its cost cutting potential. Na-ion batteries could be a suitable replacement for Li ion in small/inexpensive vehicles and for stationary storage applications where energy density isn’t as critical. The fact of the matter is that along with cost, volumetric and gravimetric energy density are the most important factors in choosing batteries for electric vehicle applications. This is why the NMC3 chemistry will remain relevant for a long time regardless of the cheaper LFP or SIB chemistry which has garnished so much attention with the run up in commodity prices in 2022. For high end applications and automakers who want the best power per unit mass or volume and are willing to spend a little more, nickel rich NMC will still be the cathode material of choice. For the cost cutting counterparts, stationary storage, and perhaps those interested in better thermal management, sodium-ion has the potential to be a contender in the coming years. Until next week,

-Grayson

Leave a like and let me know what you think!

If you haven’t already, follow me at twitter @graysonhoteling and check out my latest post on notes.

Let someone know about Better Batteries and spread the word!

Socials

Twitter - @graysonhoteling

LinkedIn - Grayson Hoteling

Email - betterbatteries.substack@gmail.com

Archive - https://betterbatteries.substack.com/archive

Subscribe to Better Batteries

Please like and comment to let me know what you think. Join me by signing up below.

LFP - lithium iron phosphate - is a cathode material in a Li-ion battery which is generally a cheaper and safer version compared to NMC or NCA (up to 200Wh/kg)

CATL reports energy density of 160WH/kg for this technology

NMC - lithium nickel/manganese/cobalt oxide - comes in various ratios of the transition metals. Commonly NMC ratios of 811, 622, or 111 (up to 300Wh/kg)